Vegetable processing

BUNKER

BF-UNI BulkFeeder

Receiving of product from trucks. Bulk Feeder is usable for many types of vegetables such as corn, green bean, green peas, spinach, broccoli, etc. Uniform feeding of product on output thanks to following bunker main parts: buffer belt, dosing belt, belt with digital weighing system, rotating rake.

WASTE CHOPPERWCH-20 WasteChopper

WCH-20 WasteChopper is intended for chopping (cutting) of biowaste from sweet corn processing line for a consistency, which is useful for following pressing in WP-20 WastePress.

WASTE PRESSWP-20 WastePress

WP-20 WastePress is designed for water removing (pressing) of biowaste from processing line, which is first chopped/cutted on WCH-20 WasteChopper.

WASHER FW-12A SeedWash

Washing, flotation, destoning and sieving function in one complex food processing machine. Washer is designed for green peas, corn kernels and broad bean. More sizes and options for different capacity requirements.

HYDRAULIC DESTONERHD-12A HydroStone

Hydraulic Destoner is designed to removing of stones, mud and other heavy particles. Prewashing, destoning and sieving function in one complex machine. Designed for green peas and broad bean.

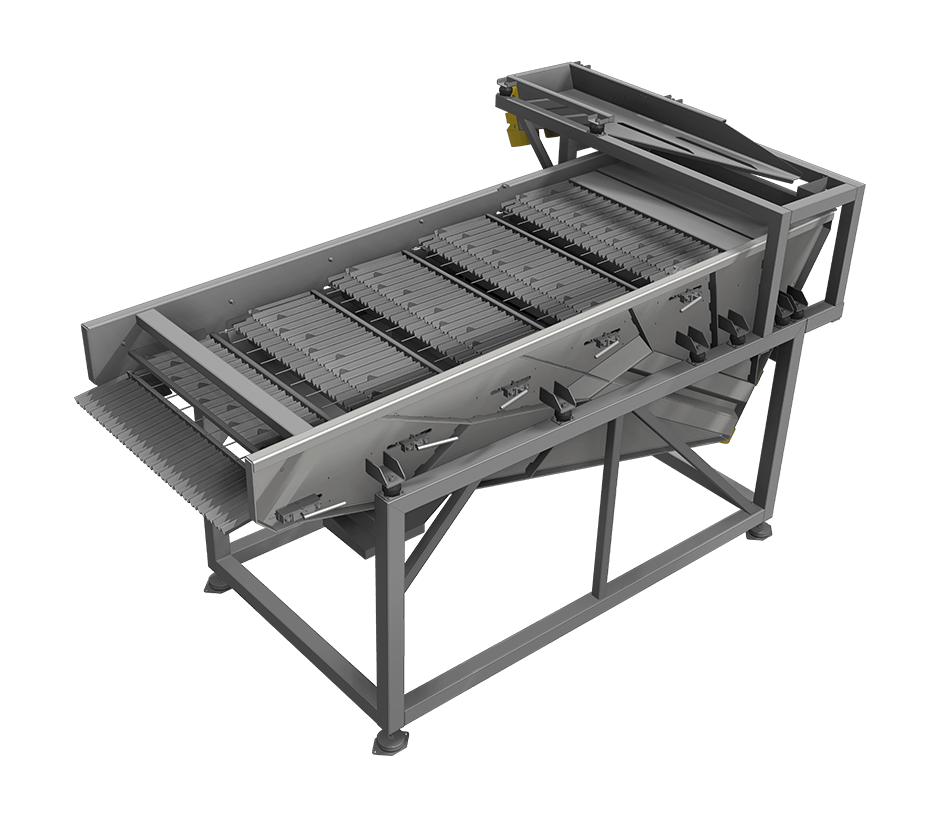

VIBRATING LENGTH GRADER BC-25 LengthCaliber

Vibrating Length grader for green bean. Multistage – repeated selection on one vibrator. Up to 5 adjustable sorting gaps to increase process reliability. Fast and easy adjustable sorting gap. Stainless steel AISI-304 execution. Driven with 2 excentric motors.

OPTICAL SORTER

OCS-1A CornSorter

5 way Corn Sorter offers very universal sorting based on size, color, shape and capacity. Software of corn sorter have function, that can automatically count amount of cobs in each grade and can dynamically change length of cobs for each grade in order to feed lines (automatic cutting, manual cutting corn on cobs) with required amount (flow dividing).

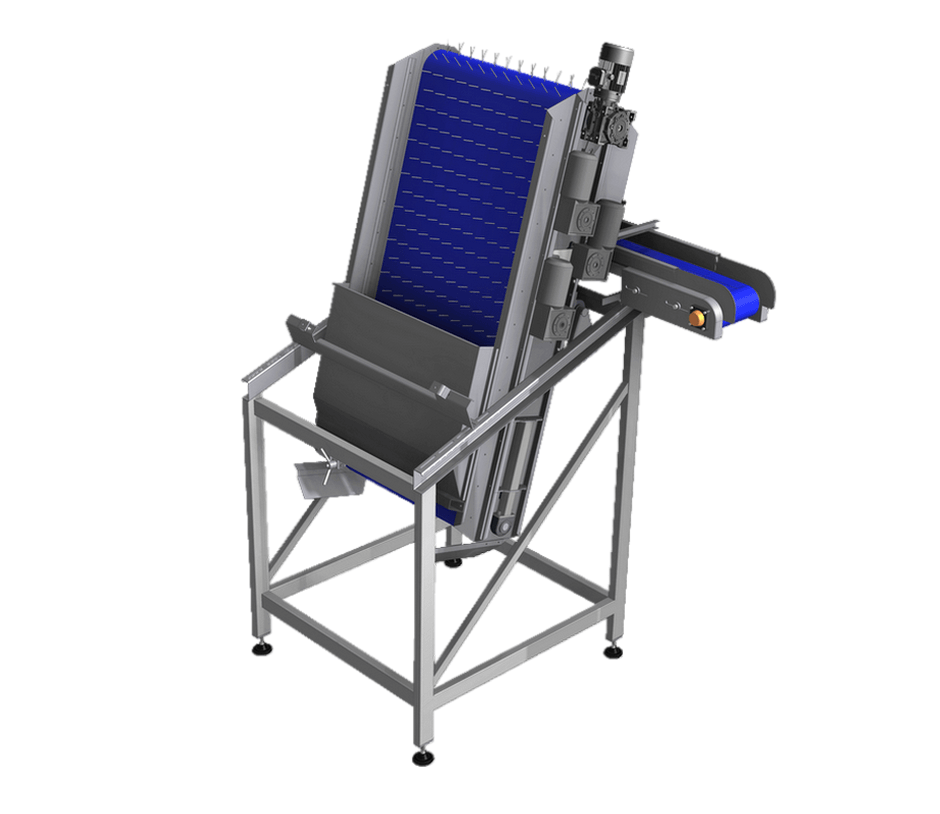

BEAN CLUSTER REMOVING BELTBD-xxA TwinRemover

Removing of bean clusters – twins on a steep belt with pins. Single beans are falling down trough pins, while twins are catched and removed. For increasing of process reliability is belt knocked/vibrating. Adjustable angle of processing “pin belt” to tune process. Perpendicular waste belt conveying waste to one side.

AIR SELECTORAS-10B AirCleaner

Air Selector is intended for removing of light parts from product (leaves) with air flow. The machine has adjustable speed of air via frequency changer (cleaning effect). Vibrating feeder ensure uniform feeding and cleaning result with 2 sieves (optional) for removing of big and small parts. Waste auger collecting all waste to one output point.

WIND SELECTOR AC-10B AirClean

Wind Selector AC-10B AirClean is designed for removing of heavy particles, stones, etc. from spinach and other leafy products. Vibratory feeder with special shape to provide proper leaves separation.

DRY CLEANING DRUM SD-20A LeafCleaner

Dry cleaning drum with perforation is removing small particles such as stones or insect from spinach leaves.

WASHER FW-12A SeedWash

Washing, flotation, destoning and sieving function in one complex food processing machine. Washer is designed for green peas, corn kernels and broad bean. More sizes and options for different capacity requirements.

SPINACH WASHERSW-10A SpinachWash

Washing in 2-3 stages depending on capacity. Big amount of paddles to deep and turn spinach leaves. Insect removing drum.

HYDRAULIC DESTONERHD-12A HydroStone

Hydraulic Destoner is designed to removing of stones, mud and other heavy particles. Prewashing, destoning and sieving function in one complex machine. Designed for green peas and broad bean.

BEAN WASHERBW-60B BeanWash

2-stage washing for higher capacity and lower water consumption. First washer with destoner, high impact spraying nozzles active water filter and powerfull pump. Second washer with washing nozzles and sedimentation tank. Water cascaded from washer to washer and recirculated.

BLANCHER-COOLERBP-xxA ThermoMaster

Blancher-cooler with multistage water circulation for blanching of various products, like green peas, sweet corn (seed or cobs), green bean, cauliflower, broccoli, pepper, spinach, etc.

TRANSPORT SYSTEM of line

Transport system of line consist of custom made elevators, conveyors and augers.

VIBRATORS

Complex transport system of line consists not just custom-made elevators and belts, but also with vibrating feeders, water transport system, flow dividers, buffers, etc.

SHARPENING MACHINE

KU-ON 1A KnifeSharper

Sharpening machine KU-ON 1A KnifeSharper is intended for sweet corn cutter knifes of KU-Z2 and CC-A2. The machine has double belt design and positioning fixtures ensure proper geometry of knifes. Includes electric system with safety function. The grinding machine has separate belt for outside and inside conus.

SWEET CORN CUTTER

KU-Z2 CornCut

This sweet corn cutter with manual feeding is intended to cut kernels from corn cobs. Corn cutter is equipped with automatic cutting head, that provides excellent cutting performance. It is possible process also shorter cobs.

AUTOMATIC SWEET CORN CUTTER

CC-A2 CornMaster

This automatic sweet corn cutter is intended for automatic cutting of kernels (seed). Advanced automatic system with camera base orienting and cutting.

CORN HUSKER

KUS-xx CornHusk

Corn Husker is intended for removing of leaves and hairs from corn cobs. Can be used for both, sweet corn and seed corn. In offer are four models CornHusk with different capacity KUS-4C, KUS-8C, KUS-12C and KUS-16C. Operation of machine is automatic, operator free.

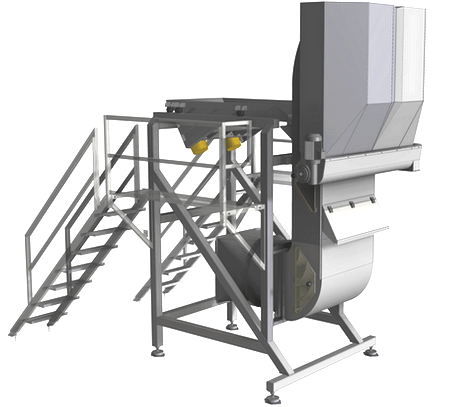

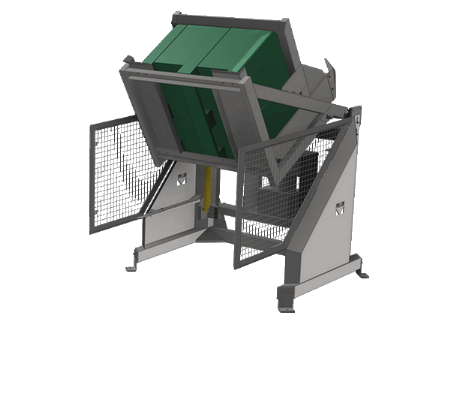

PALLET TIPPER PT-20A TippMaster

Pallet tipper is used for unloading of pallets. The machine has hydraulic system for tipping, safety side fences and optical barrier in access area.

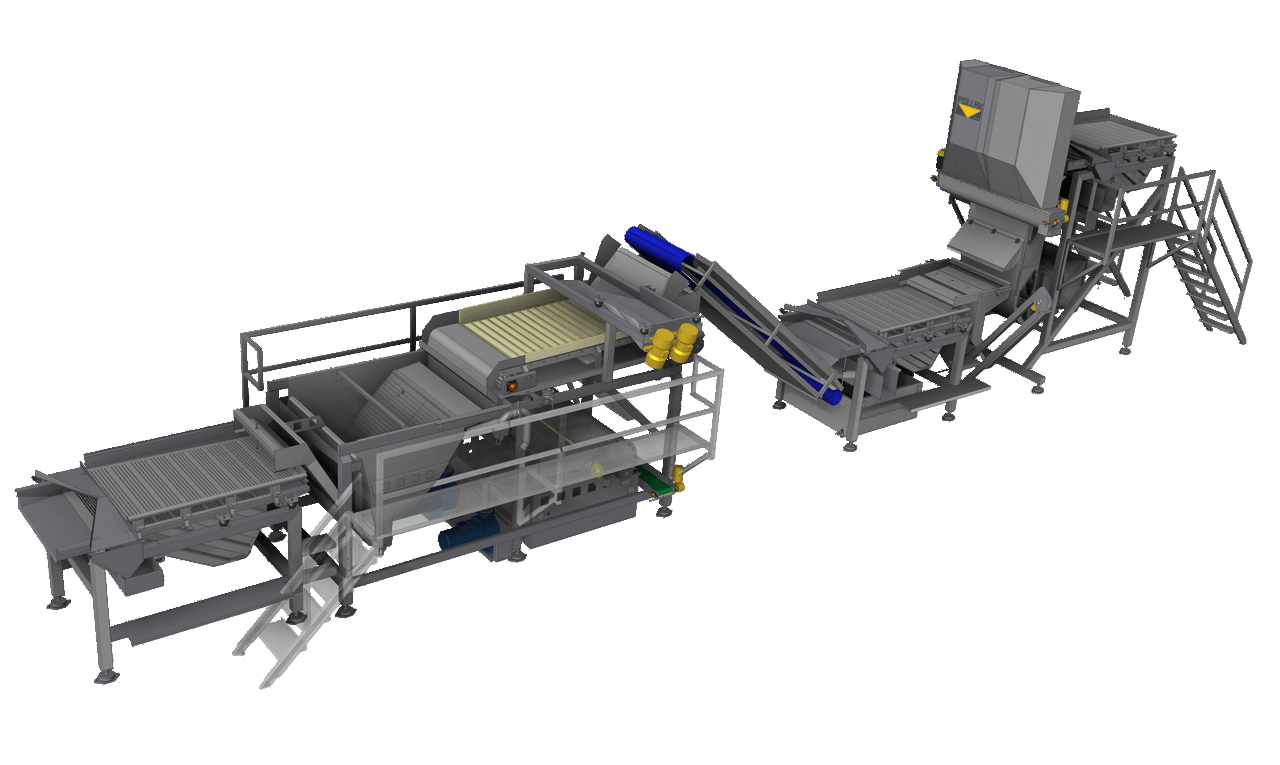

Spinach PROCESSING LINE

Complex solution for spinach processing contains except main machines like spinach washer, wind selector, dry cleaning drum, also complex transport system (belts, elevators), electric equipment, panels, wiring and other.

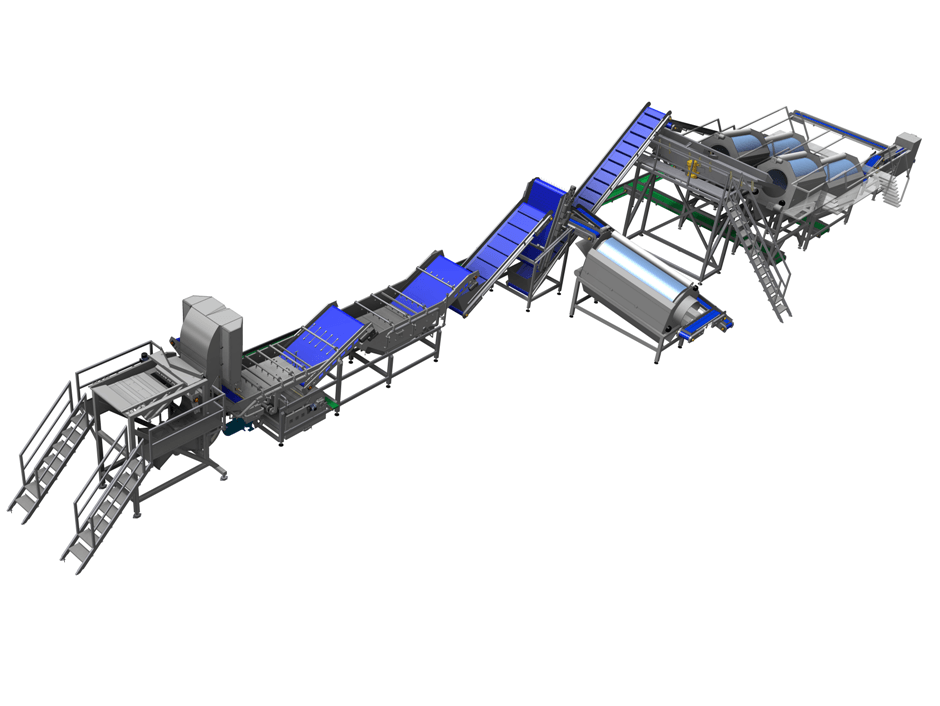

Sweet corn PROCESSING LINE

Complex solution for sweet corn processing contains except main machines like bulk feeder, husker, corn cutter, washer and blancher also vibrating selectors, technological buffers, complex transport system (belts, elevators), electric equipment, panels, wiring and other.

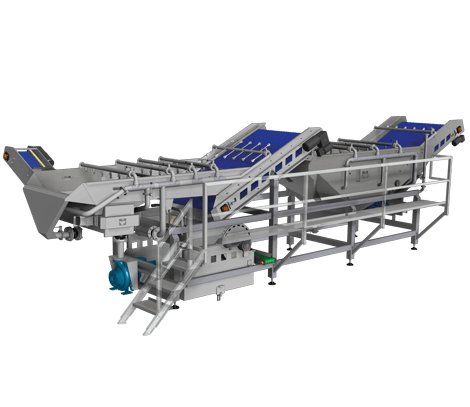

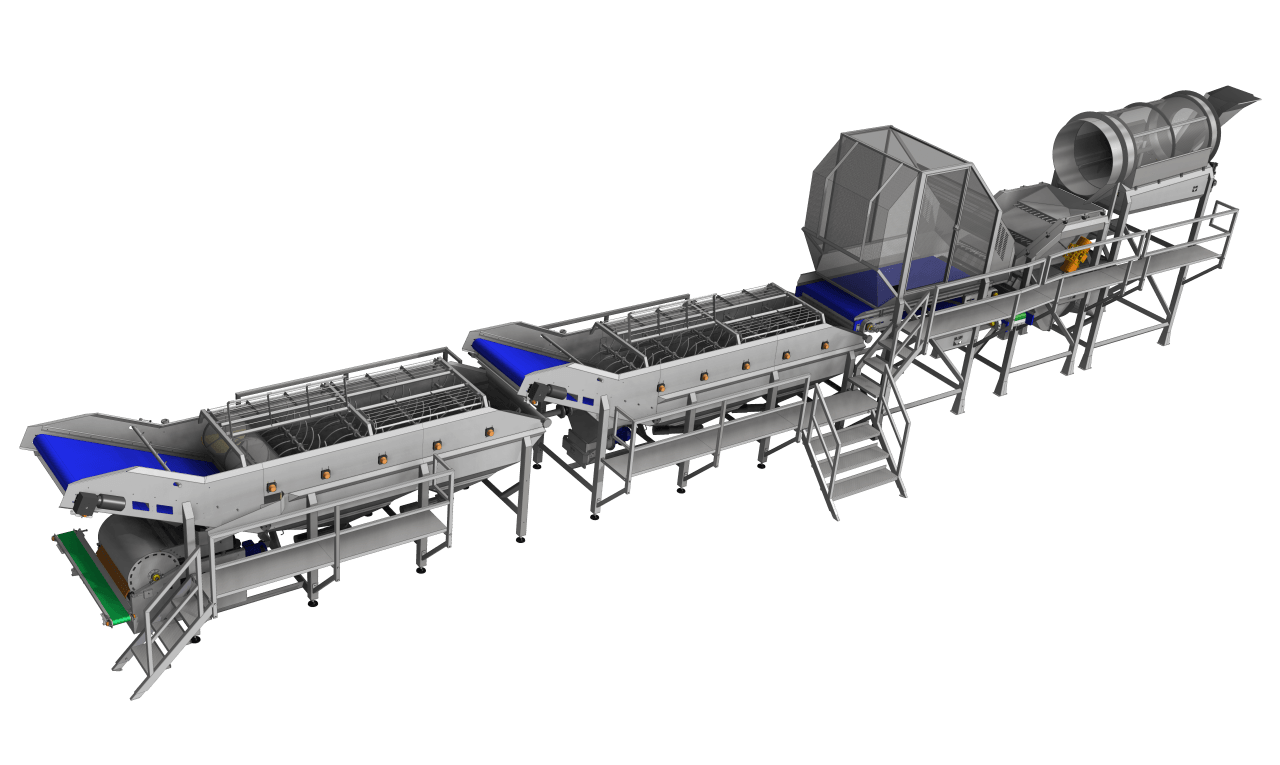

Green peas PROCESSING LINE

Complex solution for green peas processing contains except main machines like bulk feeder, air cleaner, destoner, washer and blancher also vibrating selectors, technological buffers, complex transport system (belts, elevators, hydraulic), electric equipment, panels, wiring and others.

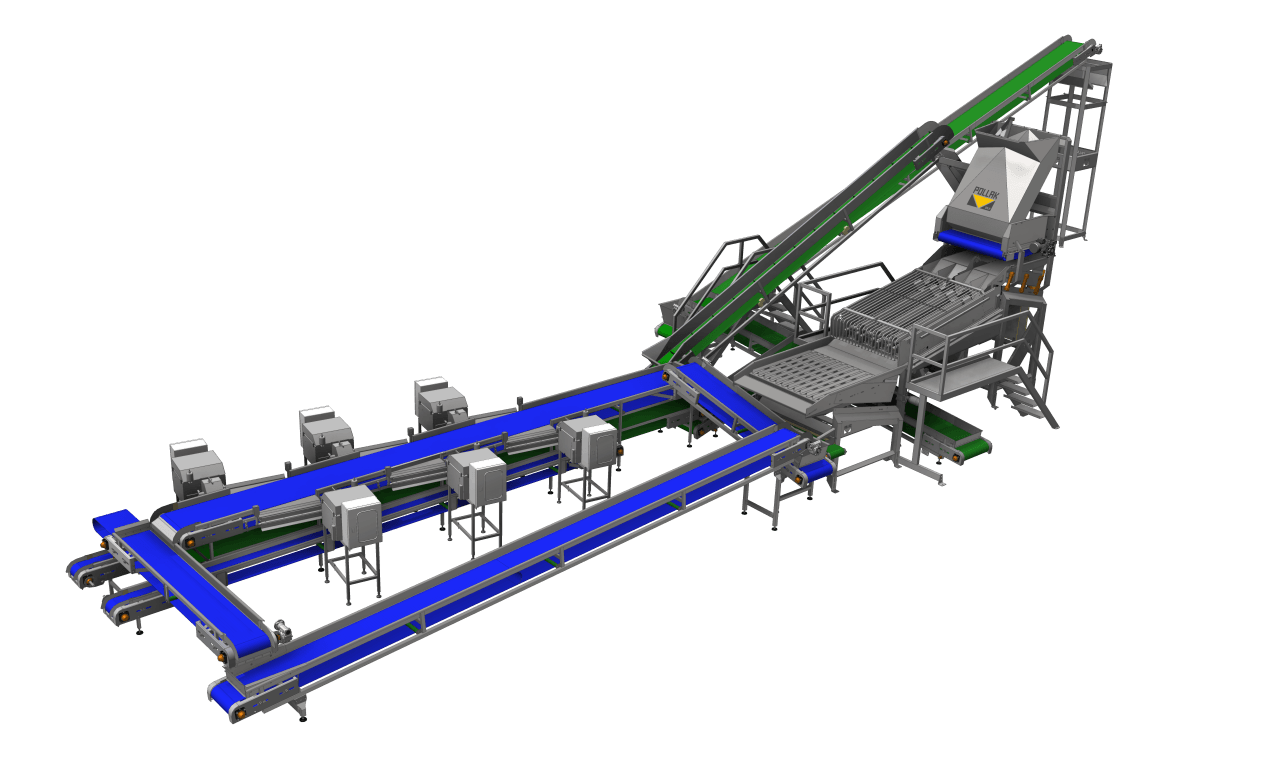

Green bean PROCESSING LINE

Complex solution for green bean processing contains except main machines like bulk feeder, air cleaner, washer and blancher also vibrating feeders, flow dividers, technological buffers, complex transport system (belts, elevators, hydraulic), electric equipment, panels and wiring.