Vegetable processing

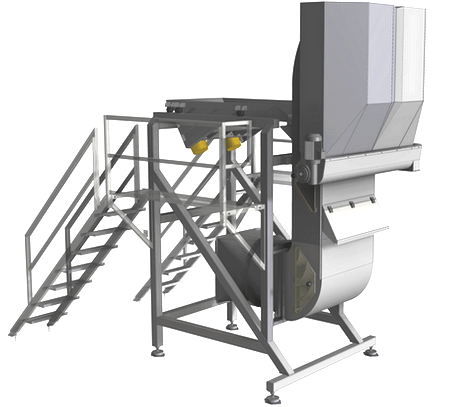

BUNKER

BF-UNI BulkFeeder

Receiving of product from trucks. Bulk Feeder is usable for many types of vegetables such as corn, green bean, green peas, spinach, broccoli, etc. Uniform feeding of product on output thanks to following bunker main parts: buffer belt, dosing belt, belt with digital weighing system, rotating rake.

AIR SELECTORAS-10B AirCleaner

Air Selector is intended for removing of light parts from product (leaves) with air flow. The machine has adjustable speed of air via frequency changer (cleaning effect). Vibrating feeder ensure uniform feeding and cleaning result with 2 sieves (optional) for removing of big and small parts. Waste auger collecting all waste to one output point.

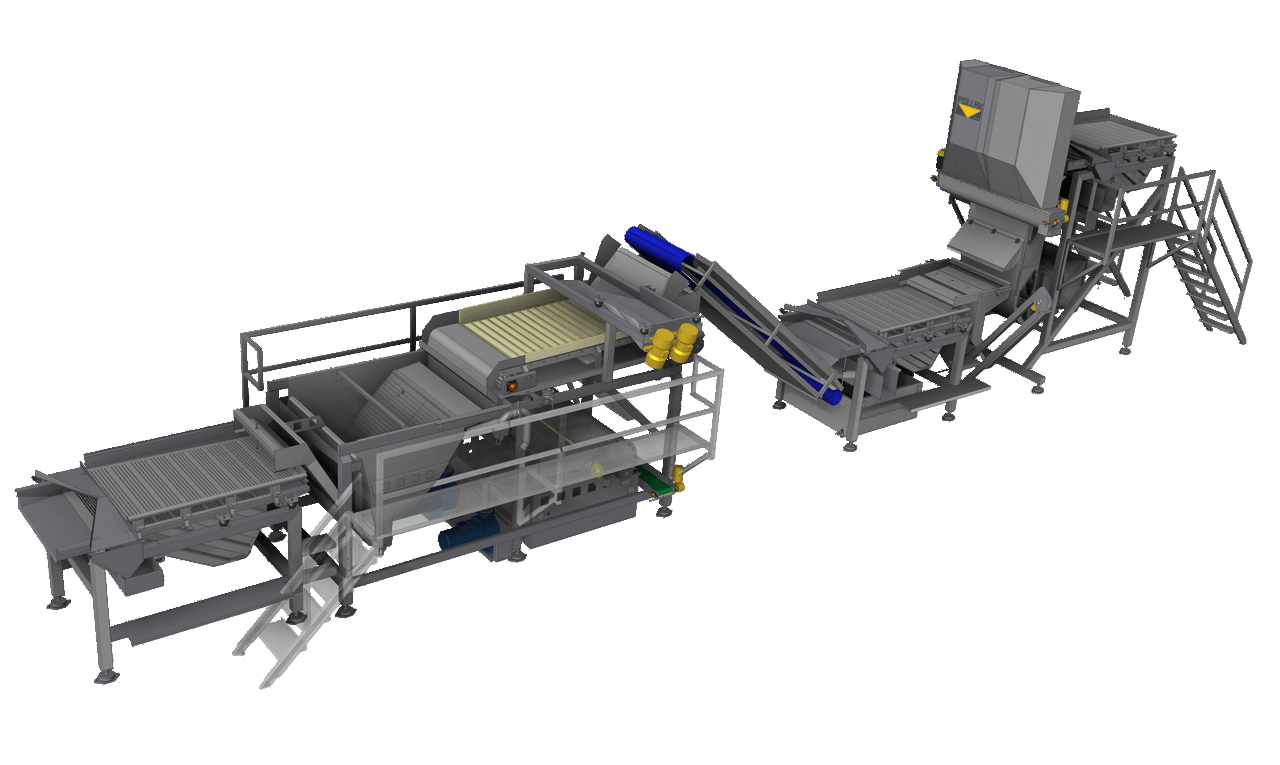

HYDRAULIC DESTONERHD-12A HydroStone

Hydraulic Destoner is designed to removing of stones, mud and other heavy particles. Prewashing, destoning and sieving function in one complex machine. Designed for green peas and broad bean.

WASHER FW-12A SeedWash

Washing, flotation, destoning and sieving function in one complex food processing machine. Washer is designed for green peas, corn kernels and broad bean. More sizes and options for different capacity requirements.

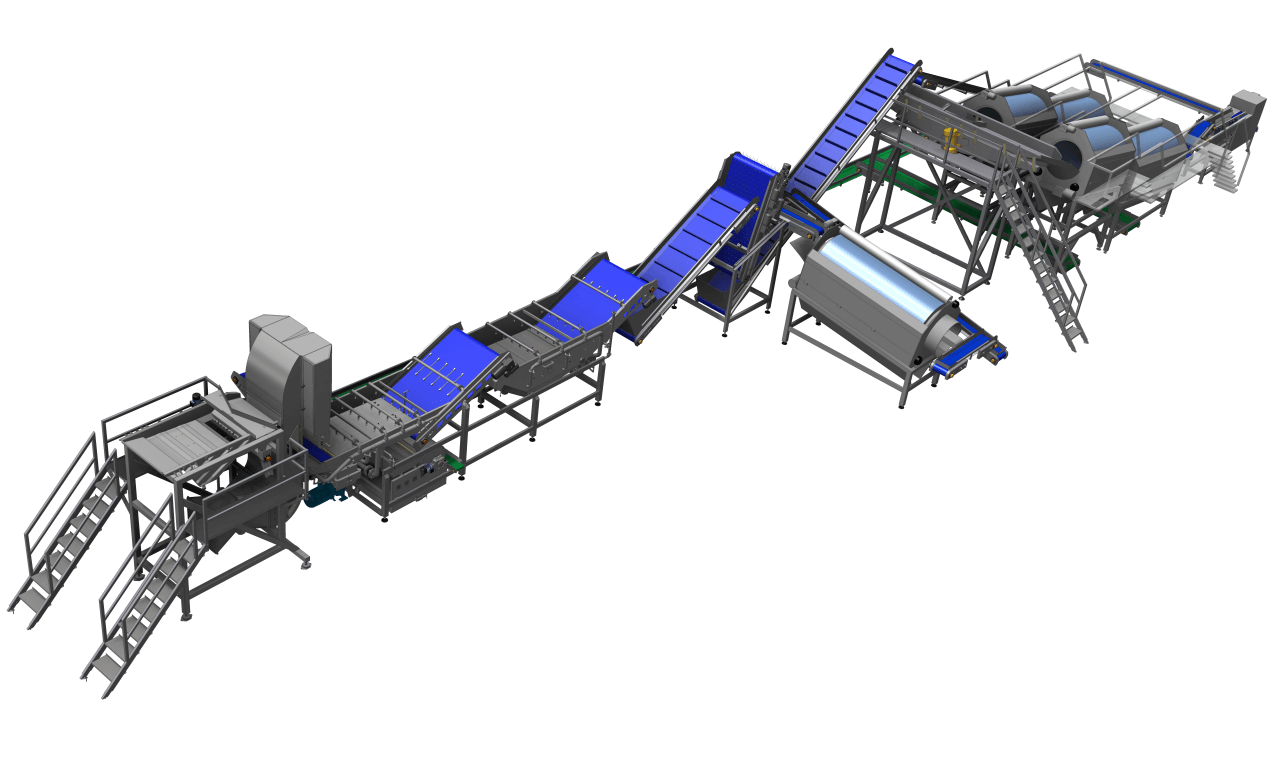

BLANCHER-COOLERBP-xxA ThermoMaster

Blancher-cooler with multistage water circulation for blanching of various products, like green peas, sweet corn (seed or cobs), green bean, cauliflower, broccoli, pepper, spinach, etc.

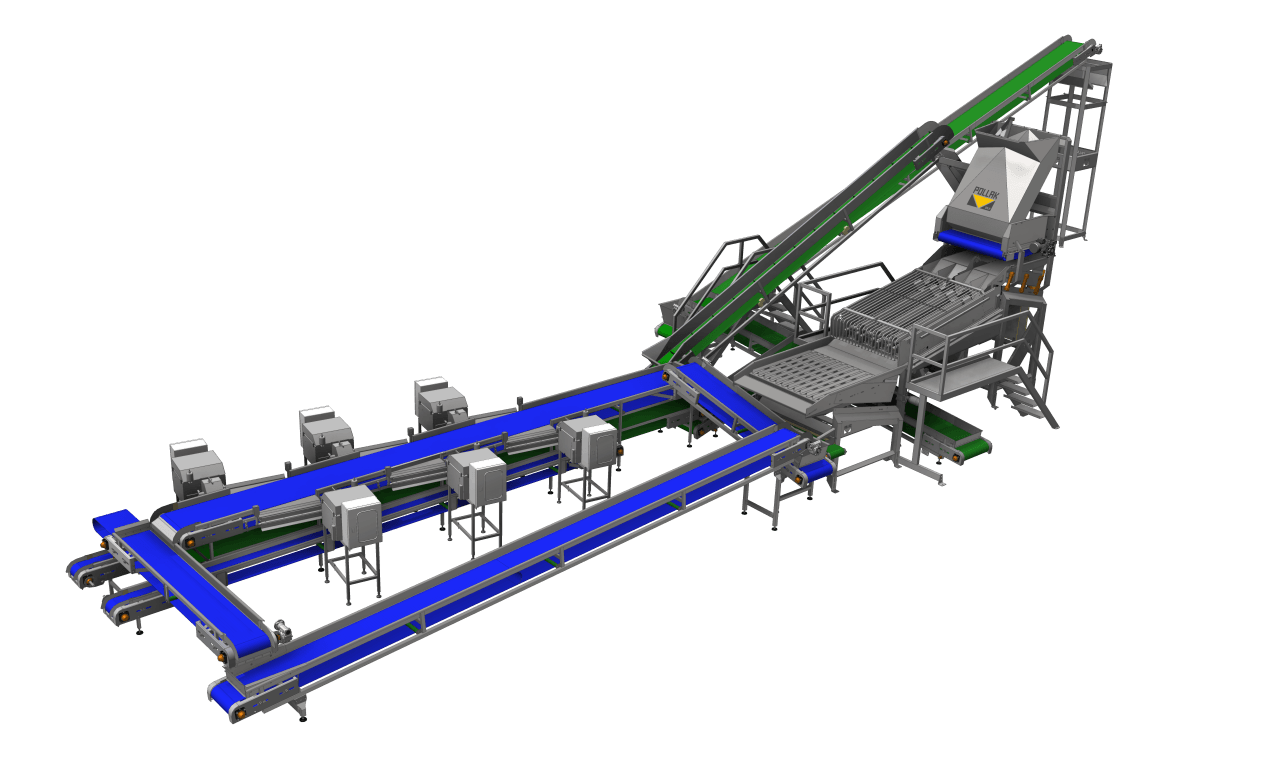

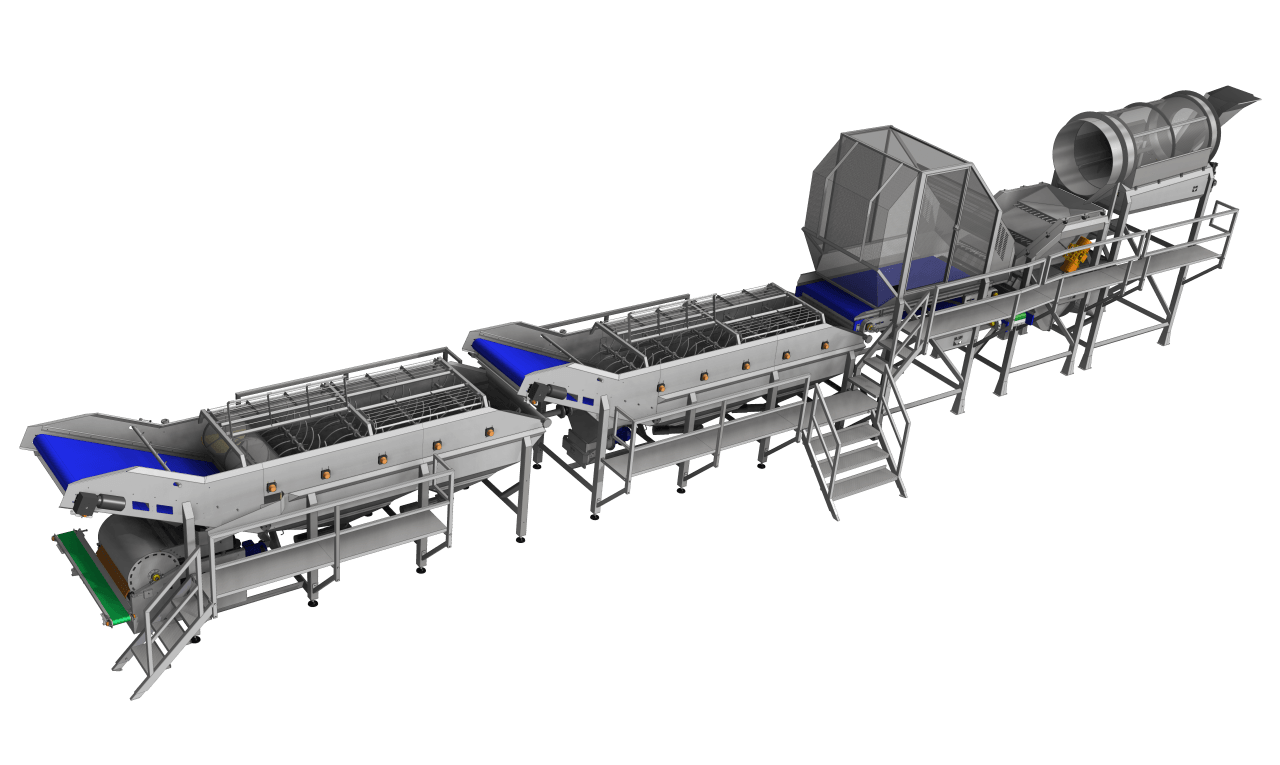

Green peas PROCESSING LINE

Complex solution for green peas processing contains except main machines like bulk feeder, air cleaner, destoner, washer and blancher also vibrating selectors, technological buffers, complex transport system (belts, elevators, hydraulic), electric equipment, panels, wiring and others.

VIBRATORS

Complex transport system of line consists not just custom-made elevators and belts, but also with vibrating feeders, water transport system, flow dividers, buffers, etc.

TRANSPORT SYSTEM of line

Transport system of line consist of custom made elevators, conveyors and augers.

WASTE PRESSWP-20 WastePress

WP-20 WastePress is designed for water removing (pressing) of biowaste from processing line, which is first chopped/cutted on WCH-20 WasteChopper.

WASTE CHOPPERWCH-20 WasteChopper

WCH-20 WasteChopper is intended for chopping (cutting) of biowaste from sweet corn processing line for a consistency, which is useful for following pressing in WP-20 WastePress.